Morgan Engineering can mobilise rapidly to your site and perform engineer services to any type of mining, mobile or fixed plant equipment.

Our ability to work in-situ saves you time and money. We’re available 24 hours per day and will arrive on-site with our service truck ready with all the tools and equipment required to get the job done. You will receive personalised advice and solutions, combined with an affordable, quality service from our team of highly skilled machinists.

Strict quality control procedures guarantee our experienced fitters overhaul components to client specification and according to the highest quality and industry standards.

Trust Morgan Engineering’s general fitting division to deliver the technical expertise and hands-on skills required to overhaul, repair, and assemble complex equipment.

As a specialist in mobile on-site milling and machining Morgan Engineering has the necessary expertise to carry out this challenging work to the highest standard.

Our highly experienced technicians can be deployed quickly to the site, along with state-of-the-art technology and specialised machinery, to identify and fix any problem. Time-consuming transport requirements and dismantling of individual parts is avoided, and on-site operations continue almost unimpaired.

Our line boring services can cater for simple procedures through to complex projects that require months of work and a specialist level of skill.

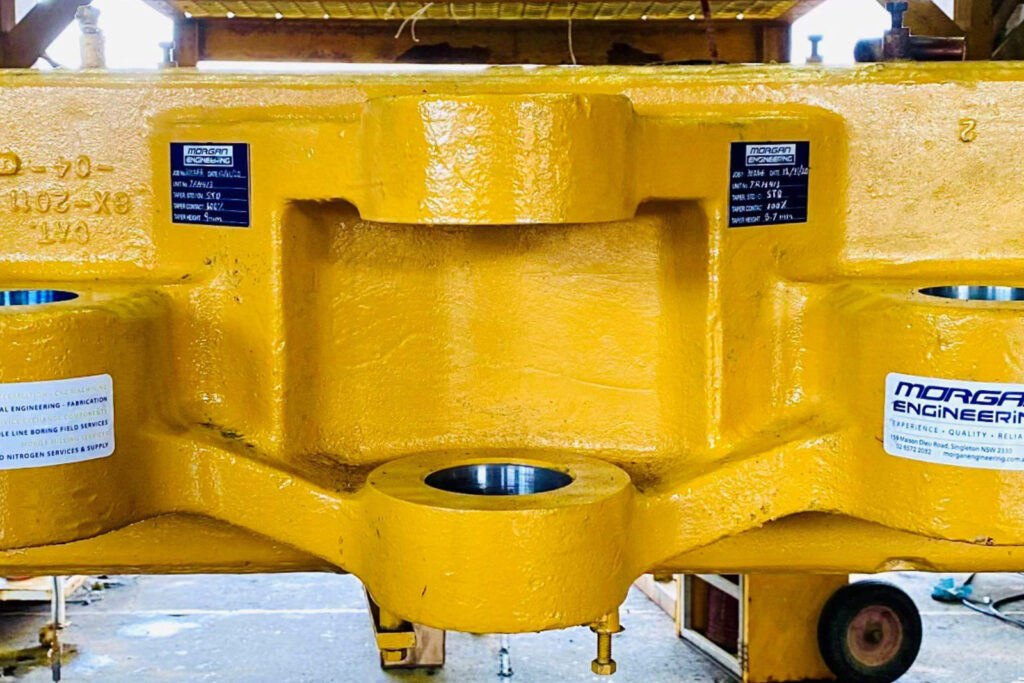

Worn pin bores, bearing housings, tunnel bores, axle pivots are usually part of fixed plant or mobile equipment that is impractical to transport to our Singleton-based machine shop.

The capability to repair on-site saves expensive downtime and transportation costs, resulting in a cost-effective and convenient services for our clients.

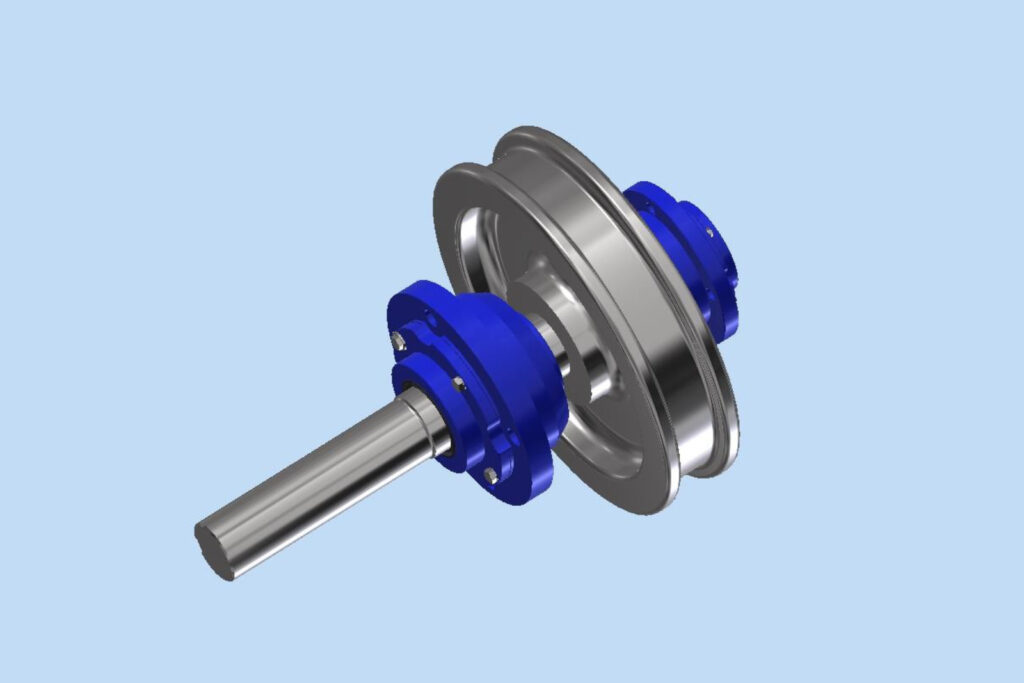

Steering tapers and bores must eventually be reclaimed with weld and machined back to a tight OEM tolerance – all while remaining in perfect alignment with all the other bores in that articulated joint.

Our in-house team developed our own proprietary equipment and techniques to machine these steer box tapers in-situ – eliminating the entire removal and offsite repair process.

This process enables us to deliver exceptional quality solutions – exceeding OEM specifications, reducing costs, and significantly reducing downtime.

Morgan Engineering’s mobile design services work in partnership with you on the design of specialist tooling for the safe removal and maintenance of components when working on heavy mobile mining equipment.

Examples include hydraulic pin removal tooling and stands for equipment and components, and customised mounting frames for machines to complete machining jobs in-situ.

Morgan Engineering is a supplier of liquid nitrogen for applications and process that require freezing.

Our handlers have been trained to the highest safety standards and are able to carry out the work to provide quality results.

We use Cookies to offer you a better browsing experience, analyse site traffic, personalise content, and serve targeted advertisement. By continuing to browse this site you will consent to our use of cookies.